PCBA processing plant is how to properly store and manage the PCBA boards that have been produced? This article will detail some common storage techniques for PCBA boards:

First, temperature and humidity control:

PCBA board meta-components are more sensitive to wet temperature. Recommended storage temperature between 15-35 degrees Celsius. Then the humidity control and between 40%-60%. If the humidity is too high, it may lead to circuit board oxidation, corrosion and other problems; if the humidity is too low, it may cause static electricity accumulation, damage to the circuit board and components.

Second, choose the appropriate storage container:

Static protection bag: static electricity is one of the common causes of damage to the PCBA board. Choose a storage bag with anti-static function, you can effectively avoid static electricity damage to the PCBA board.

Desiccant: In an environment with high humidity, PCBA boards are prone to moisture, leading to performance degradation. Adding the appropriate amount of desiccant in the storage container can keep the environment dry and prevent the PCBA board from moisture.

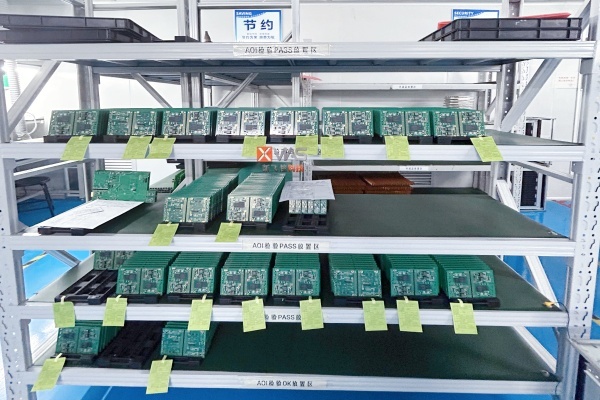

Third, categorized storage

Categorized by model: Separate storage of different models of PCBA boards, easy to find and manage. At the same time, you can avoid production errors caused by confusing models.

Categorized by function: For PCBA boards with similar functions, can be categorized and stored by function. This can quickly find the required boards when needed, improve production efficiency.

Fourth, marking management

Number management: for each PCBA board assigned a unique number, and marked on the storage container. This ensures that the target board can be quickly found when needed.

Record information: On the basis of the number, the establishment of detailed record information, including the board model, production date, batch number and so on. This information helps to trace the source of the boards and quality issues.

V. Regular Inspection and Maintenance

Inspection of storage containers: Regularly check the integrity of storage containers to ensure that there is no damage or deformation. If it is damaged, it should be replaced in time.

Check the status of PCBA boards: Regularly check the status of PCBA boards, including whether there is damage, moisture, deformation and so on. If problems are found, they should be dealt with in time.

Cleaning and organizing: Regularly clean and organize the storage containers to keep the environment neat and orderly. At the same time, the expired or no longer used PCBA boards are properly disposed of.

Six, the use of professional tools and equipment

In the storage process, you can use some professional tools and equipment to improve efficiency. For example, the use of tools with anti-static function to carry PCBA boards; the use of professional storage rack to store the boards and so on. These tools and equipment can ensure that the storage process will not cause damage to the PCBA board.

By mastering these skills and putting them into practice, you can realize the efficient and orderly management of PCBA boards, which provides strong support for the next step of production and inventory management.