In the electronics manufacturing industry, FPC flexible circuit boards once became the highlight of the electronics manufacturing industry because of their unique high flexibility, thinness and excellent electrical properties. As a supplier in this field, xvias Technology's process flow and technical strength in FPC flexible circuit board processing projects have attracted much attention. This article will be an in-depth analysis of xvias technology FPC flexible circuit board processing project a variety of processes.

First, raw material selection and preparation

Our strict screening of polyimide film and other high-quality flexible substrates to ensure that the raw materials of high quality. At the same time, the conductive layer of material selection of high-quality copper foil to ensure the conductivity of the circuit board. In addition, the selection of insulation layer is also strictly screened to ensure the stability and safety of the circuit board.

Second, the equipment configuration and process parameters set

In the equipment configuration and process parameter settings also has a unique advantage. xvias Technology is equipped with advanced flatbed printing machines, etching machines and other equipment, and according to the characteristics of raw materials and product requirements, set precise process parameters.

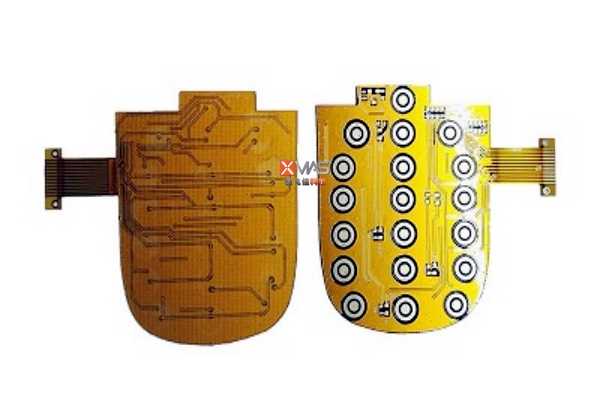

Process Flow

xvias Technology strictly controls the FPC flexible circuit board processing project. First, the conductive layer material is applied to the flexible substrate through the printing process to form the required line pattern. Then, etching technology is utilized to remove the unwanted portion of the conductive layer, leaving the precise lines. Next, a copper foil stripping process is performed to enhance the flexibility of the board. Finally, according to the design requirements for bending, shearing and other processing processes, made of the desired shape of the FPC flexible circuit board.

Fourth, the key links and precautions

During the processing of the project, equipment maintenance, process optimization and quality control are the key links. xvias pays attention to the daily maintenance and repair of equipment to ensure stable operation and efficient production. At the same time, the company continuously optimizes the process flow and parameter settings to improve production efficiency and product quality. In addition, the strict quality control system ensures that each FPC board meets high quality standards.

V. Application Scenarios and Effects

xvias's FPC flexible circuit boards are commonly used in electronic equipment, automotive, medical and other industries. Their thin, light and flexible characteristics provide more possibilities for product design, and at the same time enhance the performance and experience of the product.