In the process of SMT chip processing, the three welding technology methods to realize the interconnection of component wires include lap welding, hook welding and winding welding. New Feijia technology will now provide you with a detailed analysis of the characteristics and application of these three basic welding methods.

1. Lap soldering:

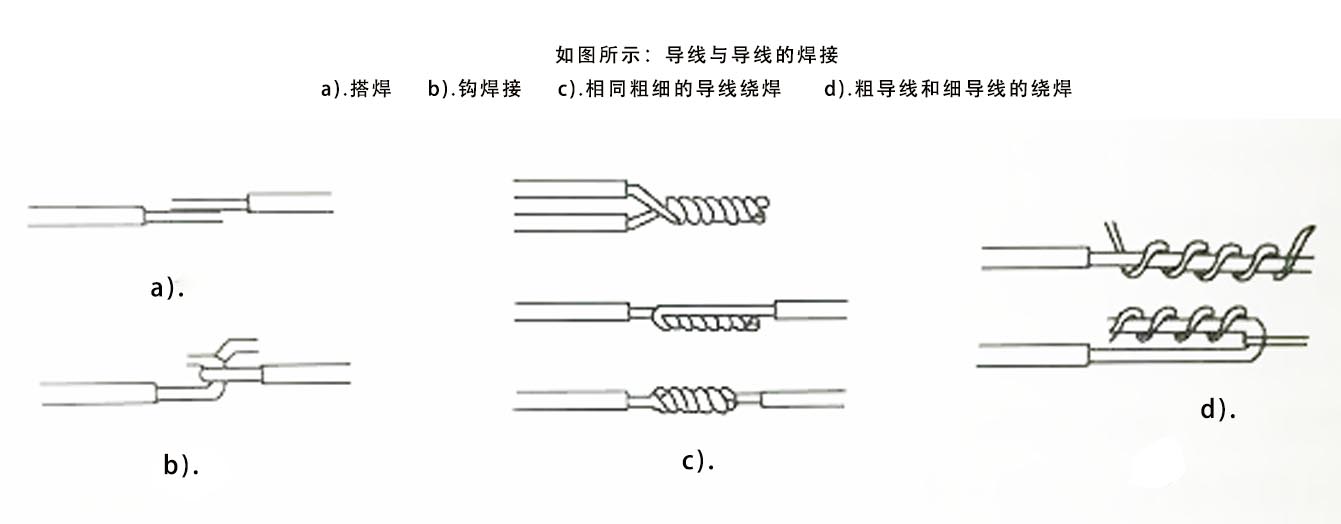

The tinned wire will be gently over the other similarly treated wire to be soldered. This technique is easy to operate, but its firmness and reliability is not good, so it is mostly used in the maintenance and inspection process of temporary wiring solutions, or those who are difficult to implement the winding welding, hook welding of special parts, as well as to cope with some of the plug-in longer welding needs. The key to operation is to maintain a stable wire from the initial soldering to the solder is fully cured during the period, as shown in the figure.

2. Hook soldering:

By first bending the tin-plated wire into a hook shape, and then closely hooked with another wire, and the use of pliers to fix, and then soldering, the specific steps shown in Figure B. Although the structural strength of hook welding is slightly lower than that of winding welding, it has become another practical welding option because of its easy and fast operation process.

3. Winding welding:

The tinned wire is wound and pulled tightly and then soldered. The thickness of the wire is different, around the welding method is different, if the wire has a thick and thin, can be thin wire winding to the thick wire, if the wire is the same thick and thin can be taken to twist and tighten the method. Specific winding method shown in Figure a, b. Welding around the highest reliability, so in the wire and wire welding is generally used around the welding method. Connection between the wire to the main winding welding, welding around the operating steps are as follows:

(1) According to the requirements of the wire to remove a certain length of insulation overlay;

2) 2) Pre-weld the wire;

3) 3) Sleeve the wires with heat-shrinkable tubing of suitable diameter;

4) Strand and solder two or more wires;

5)Sleeve the heat shrink tube while it is hot, and fix the heat shrink tube on the joint of the wires after the welding place cools down.

Welcome to learn about the treasure trove of component knowledge in the field of SMT chip processing prepared by Xinfeijia Technology, and we look forward to this information being of great help to you. To explore more specialized knowledge, please visit our official website https://www.xvias-pcba.com/, Xinfeijia Technology with you, in the world of SMT chip processing electronics manufacturing continue to explore forward!